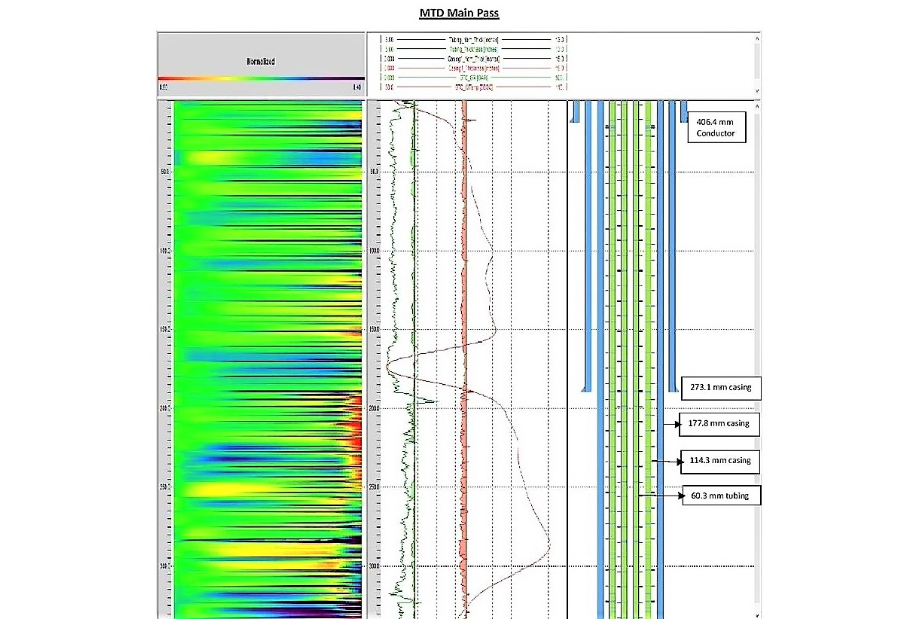

The Magnetic Thickness Detector (MTD) is a 1-11/16 in O.D electromagnetic corrosion measuring instrument primarily run through tubing with the unique ability to simultaneously inspect tubing and the casings behind it. The integrity of the casing string can be evaluated with neither the requirement for costly workover rig, nor the time-consuming removal of the tubing completion.APC OFS’s next generation MTD tool can evaluate quantitative thickness measurements up to three concentric pipes. The state-of-the-art instrument combines a high-power transmitter, improved signal-to-noise (SNR) electronics and fully configurable acquisition. This flexible approach allows a wide range of evaluations under different conditions and conveyance systems.A simple engineer selection of the functional mode allows features such as:

- Log up to 18-5/8” casing

- Simple mode selection

- Fast logging of single strings

The tool samples the pulsed eddy current transient decay response every 1ms for a duration controlled by the logging mode. This data can be transmitted real-time to surface or stored downhole during memory logging as the MTD tool is fully PegasusStar compatible.When run with our PegasusStar platform, the MTD is fully combinable with Multi-Finger calipers (MFC), Gamma-Ray/Temperature/CCL (GTC) and our Digital Radial Bond Tool (RBL). The combination provides a comprehensive evaluation of the well integrity, providing accurate thickness information for multiple pipe strings as well as the cement bond quality